Semi-finished product testing

Semi-finished product testing verifies the quality and consistency of materials before they enter further production stages. Bars, wires, tubes, and profiles must meet defined specifications to ensure that downstream forming and machining deliver reliable results. FOERSTER technologies provide non-destructive insight into structural integrity, helping maintain process stability and product performance.

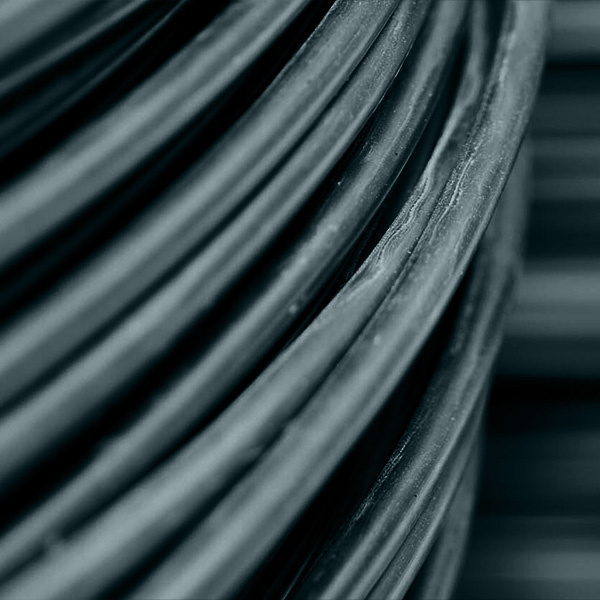

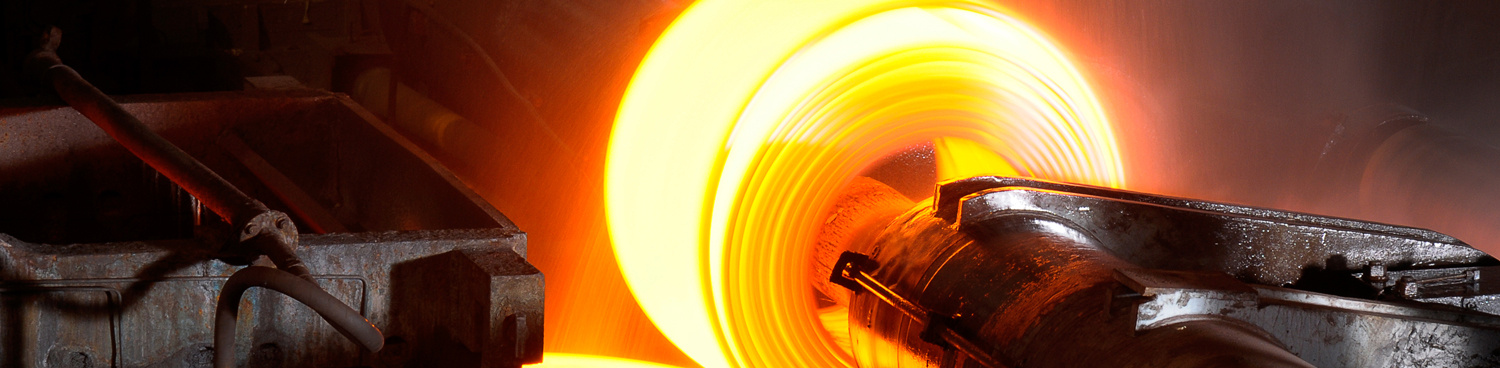

Wire

Wire refers to long, slender metal products manufactured in continuous lengths through drawing or rolling processes.

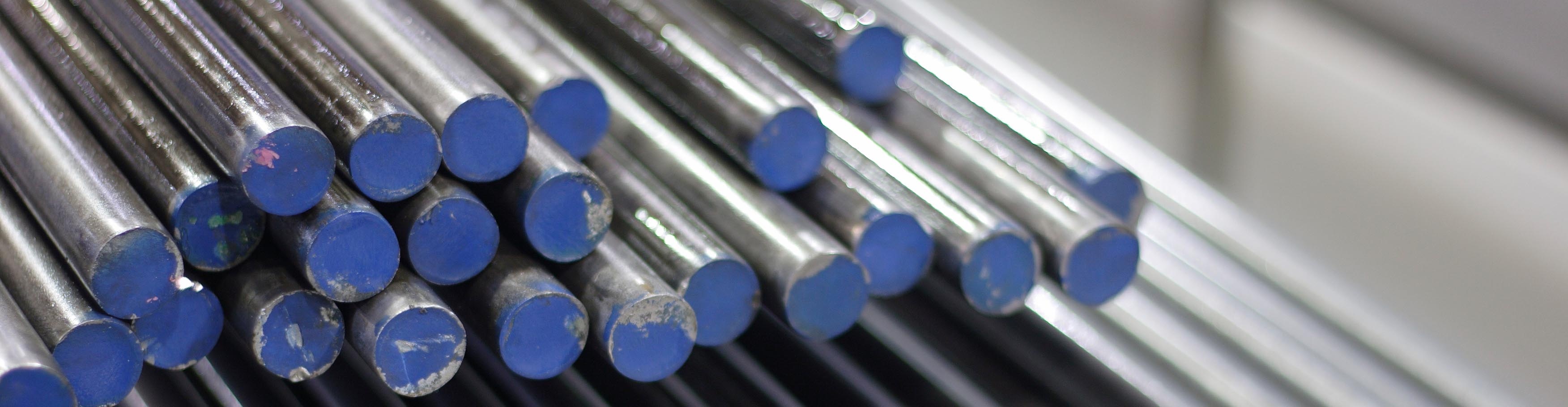

Rod

Bars are solid, elongated metal products with round, square, or polygonal shapes, produced through rolling, pressing, or drawing. They offer high strength, precise dimensions, and are widely used in the machinery, automotive, construction, and manufacturing industries.

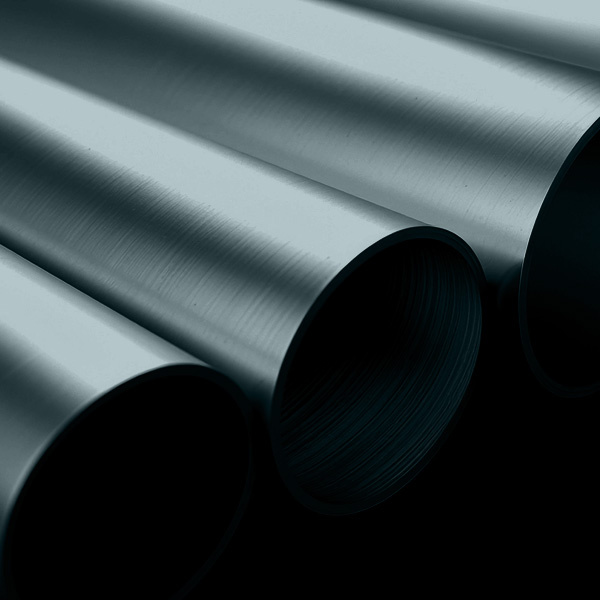

Tube

Pipes are hollow, cylindrical products made from metal or other materials, produced in continuous lengths and used for transporting liquids, gases, or for structural applications.

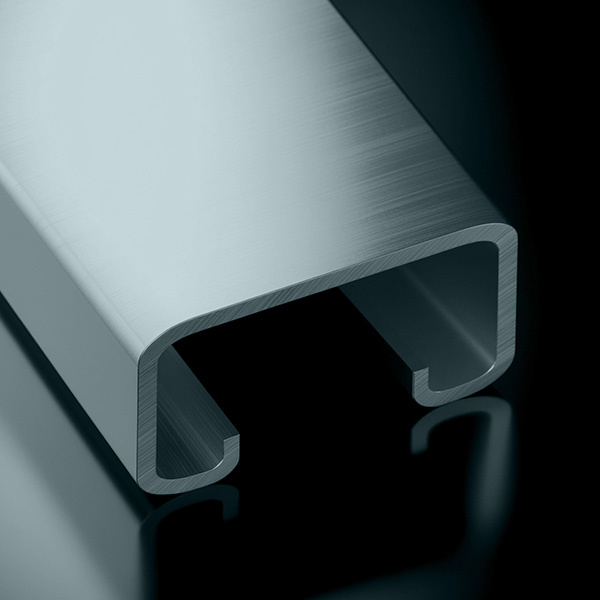

Profile

Profile sind längliche, geformte Produkte aus Metall oder anderen Materialien, die durch Walzen, Pressen oder Strangpressen hergestellt werden und für strukturelle, konstruktive oder funktionale Anwendungen eingesetzt werden.

Billet

Billets are solid, square or round metal semi‑finished products produced by casting or rolling. They offer high strength, consistent material properties, and serve as base materials for manufacturing bars, profiles, tubes, or forged components.

Strip / plate

Strip and sheet are flat metal products manufactured in continuous lengths or cut formats by rolling. They offer high strength, precise dimensions, and are used in a wide range of industrial applications such as forming, stamping, and structural components.